Fiber Plast

Offer

The Fiber Plast mass is delivered in dry bulk form and after moisturization with water and mixing produces use-ready uniform consistency with good lubricity and adhesion.

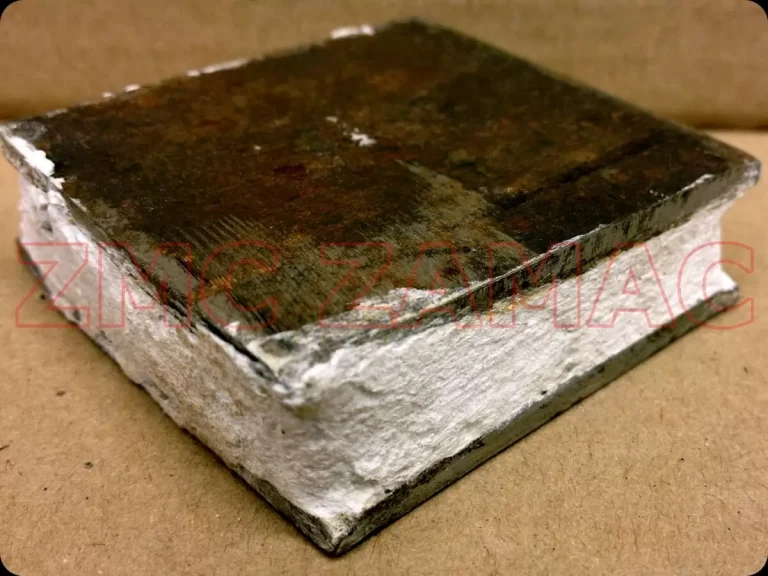

Fiber Plast – insulation-repair mass.

ZAMAC ZMC is the only manufacturer of Fiber Plast. Buying from us, you can be sure that mass is new of full value.

Characteristics:

- good plasticity and lubricity

- low shrinkage in the drying and firing process

- resistant to sudden temperature changes

- doesn’t crack or peel

- in most applications ready for work after drying

- good adhesion to most substrates

- suitable for mechanical processing

- fills hard-to-reach areas very well

Methods of application:

- putty knife,

- trowel

Application:

- protection and repair of the covers of foundry ladles

- insulation of a foundry ladle – first layer from the surface

- thermal protection of steel structures

- protection for refractory fiber insulation modules

- refractory dilatation

- filling of the doors, sight glasses and manholes of heating boilers

- thermal insulation of tanks or protective layers exposed to temperature

- insulation of cable trays, electric cables, flues

- insulation of casting runners for non-ferrous metals

- repair of damaged and worn linings of heating units

- preparation of various types of seals

- refractory mats stiffening agent

- thermal insulation of the inductors in induction furnaces

- manufacture of insulation fittings

- prevents the defibration of linings

- recommended in the embedding of burners

- replacement for refractory cardboard

- protection for materials with a lower temperature classificatio

| FP-A | FP-B | |

|---|---|---|

| Use temperature | 1260°C | 1350°C |

| Parameters of mass fuel at application temperature: | ||

| Apparent density | 500 kg/m3 | 500 kg/m3 |

| Compressive strength | 0,8 – 2 MPa | 0,8 – 2 MPa |

| Linear shrinkage | 1% | 1% |

| Thermal conductivity(W/m*K): | ||

| 400°C | 0,11 | 0,12 |

| 800°C | 0,15 | 0,16 |

| 1200°C | 0,22 | 0,22 |